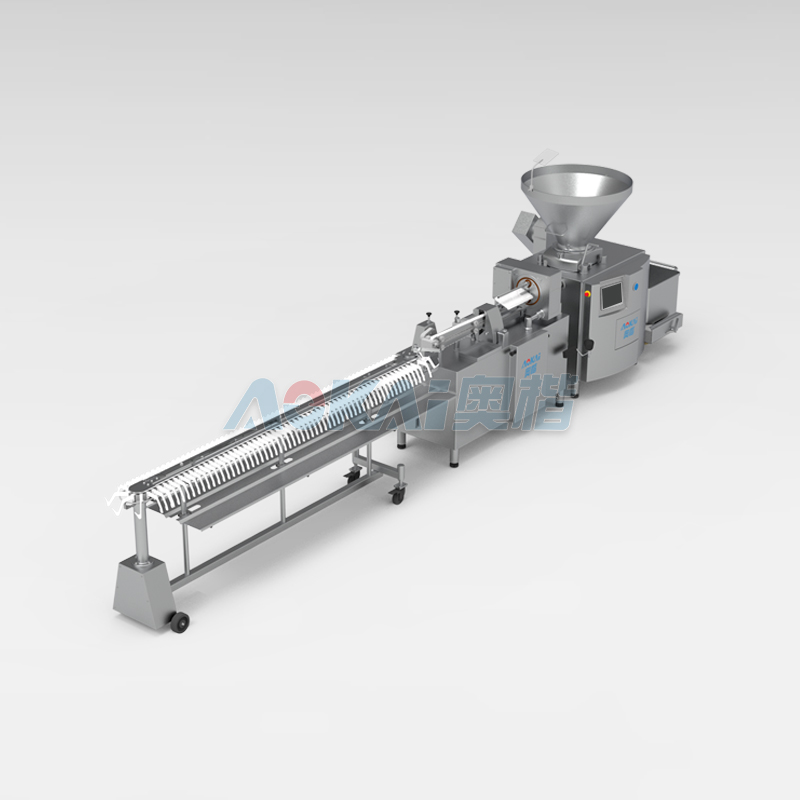

Vacuum filling machines is suitable for quantitative filling, portioning and conveying functions of sausage, ham, ultra-light clay, colloid and other fluids and semi-fluid, paste, mash, and organized blocks. Vacuum stuffer is applicable for varieties of casing: natural casing, collagen casing, cellulose casing and plastic casing, etc. Quantitative range: 5~10000g. Quantitative accuracy: ±1g/100g. Vacuum filler can used with clipper machine, twisting machine and tying machine.

EmailMore

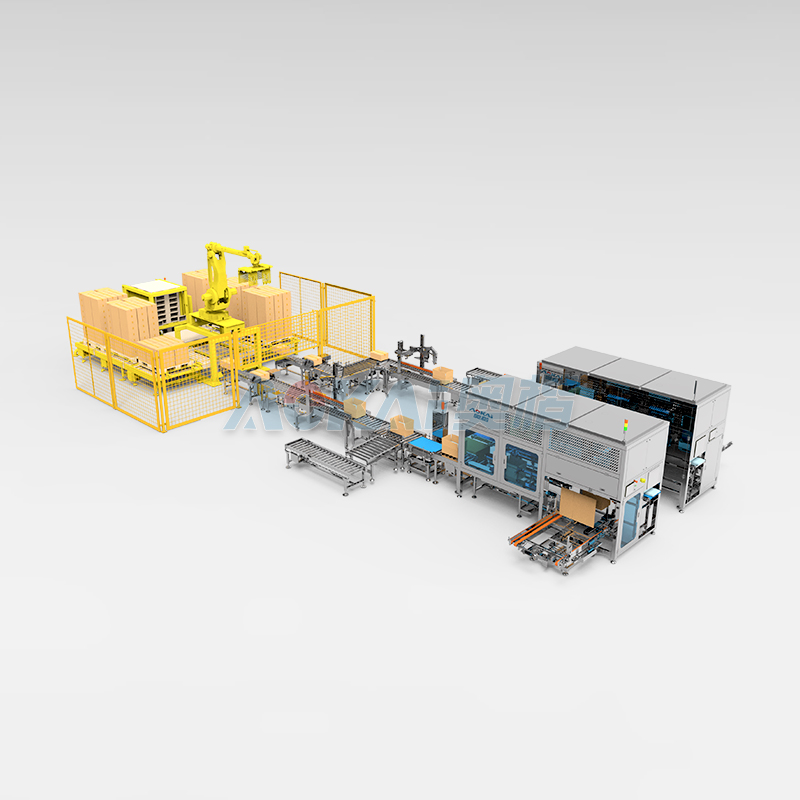

Intelligent dual parallel packing robot with vision, auto-recognize/position. Fits Robotic Packaging System, efficient pick-and-place. High-speed Automatic Box Packing Machine, sausage-compatible, meets Robotic Packaging needs. Integrates Palletizing Robot & Industrial Automation Packaging Line, boosting automation.

EmailMore

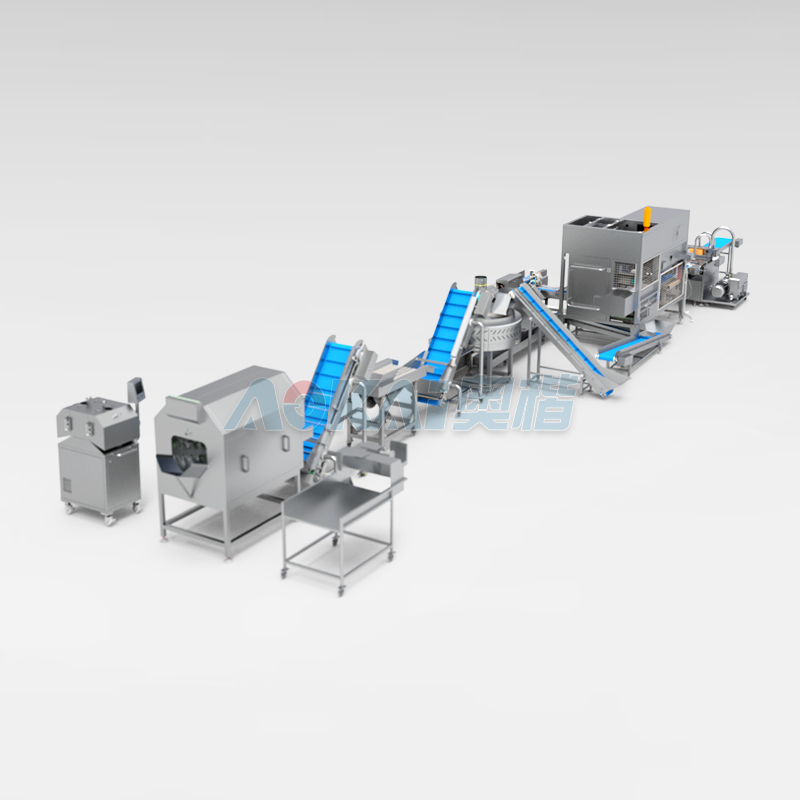

Automatic Sausage Bagging Line: Combines vibrating screener, arranger, grabber, heat sealer. Removes impurities; aligns sausages, works with sausage loading machine. Feeding machine, automatic feeding machine enable set-count packing via sausage packing machine. Links to sausage making machine; customizable, scalable. Boosts efficiency, cuts manual work.

EmailMore

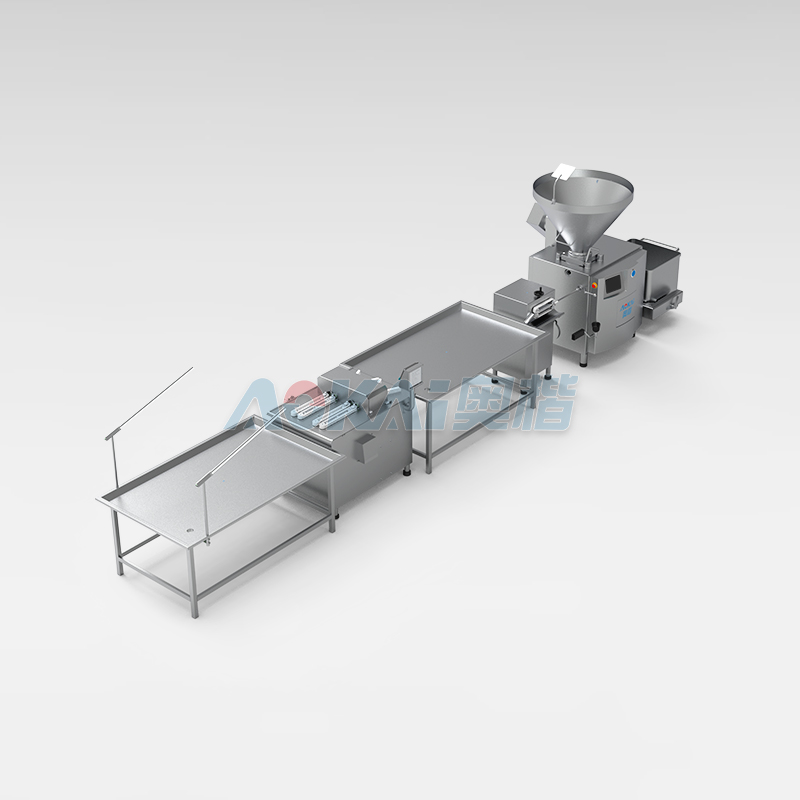

High-automation sausage filling and tying machine, fast, large capacity. Sausage machine making with length control, fits collagen, natural, plastic casings. Sausage binder & filler saves casing cost. Vacuum stuffer line with threading machine uses SUS304 stainless steel. Neater than twisted, no extra casing lumps.

EmailMore

Dual Channel Sausage Twisting Line boosts casing efficiency and single-line output significantly. Sausage linking & hanging system completes vacuum filling, extending sausage shelf life. Fully automatic sausage line: high efficiency with quantitative and fixed-length functions. Sausage-making machines use SUS304 stainless steel.

EmailMore

Bowl cutter is with a temperature detection device, it can measure the temperature change of raw materials during the chopping process; The bowl cutter adopts three cutters and cooperates with frequency conversion speed regulation to complete the chopping, emulsification and mixing at one time; The chopping time is short, the temperature of the product is small, and the taste and yield of the product are effectively improved;

EmailMore