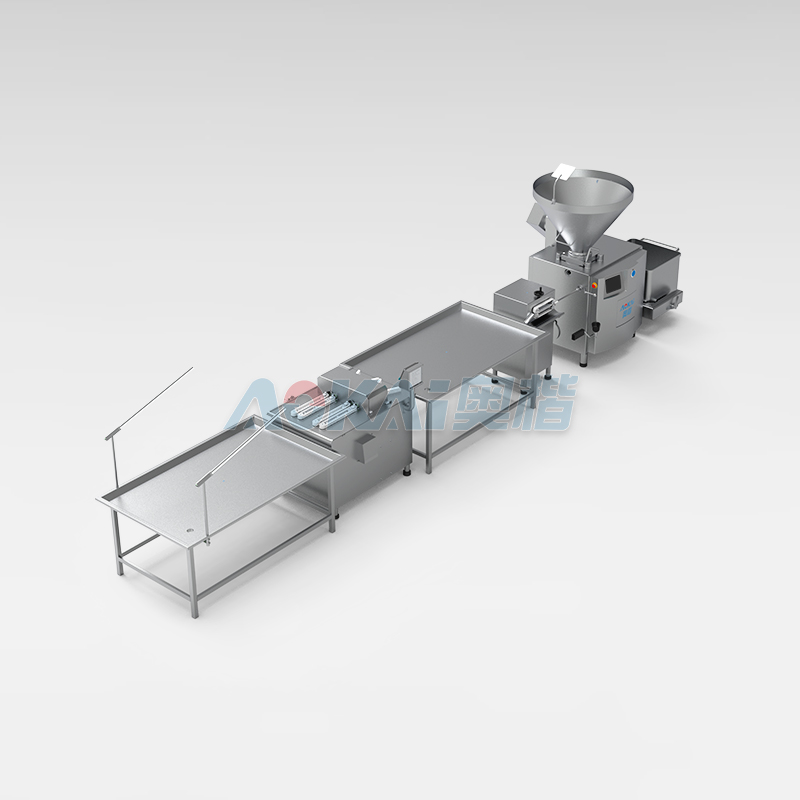

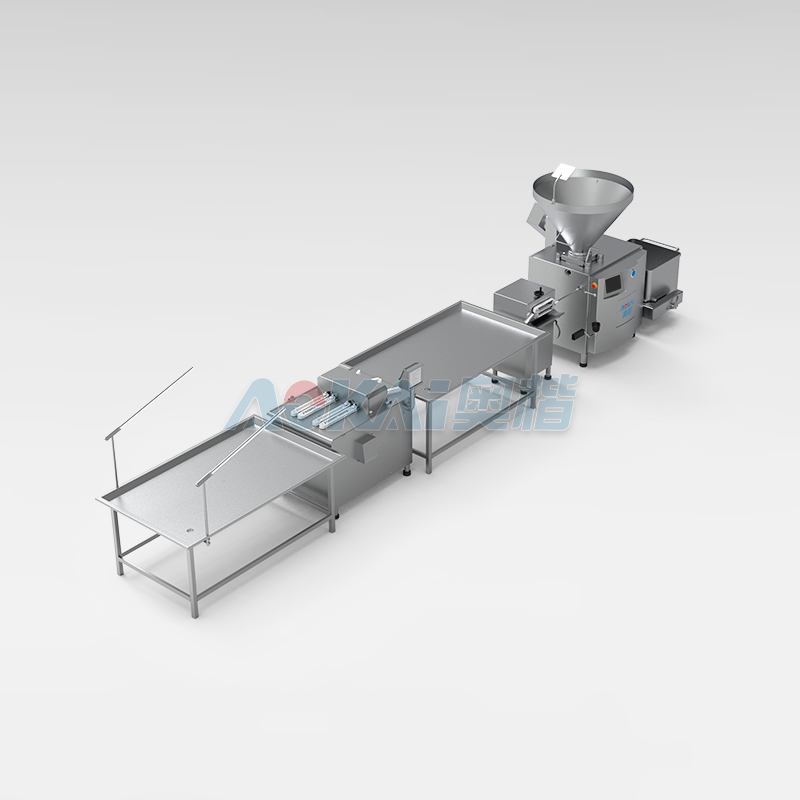

Dual Channel Sausage Tying Production Line

- Aokai

- Foshan,Guangdong,China

- 15-20 days

- 45 sets/month

Dual Channel Sausage Tying Production Line

Key Features & Advantages:

1. Enhanced Product Quality: Featuring a vacuum filling machine as the core, this sausage filling and tying machine completes raw material filling in a vacuum state. It effectively prevents fat oxidation, avoids protein hydrolysis, reduces bacterial survival, and ensures a longer product shelf life. The sausages stay tender with a long-lasting flavor – your customers will notice the difference.;

2. Superior Vacuum Performance: With a vacuum degree reaching -0.1MPA, the vacuum stuffer sausage system guarantees optimal filling conditions, so your products maintain consistent quality batch after batch.;

3. High Efficiency & Consistency: This highly automated sausage machine making line offers high speed and large production capacity. It ensures the weight, length, and quality of final products stay within high-standard ranges, cutting waste and making your production line run smoother.;

4.Versatile Casing Compatibility: The sausage tying machine adapts to collagen, cellulose, animal, and plastic casings, giving you the flexibility to meet diverse production needs and expand your product range with ease.;

5. Cost Savings on Casings: It significantly saves casing usage – about 600 meters/ton for 125mm length, 38g weight products; around 1600 meters/ton for 50mm length, 10g weight ones. This lowers material costs, putting more profit back into your business.;

6. SNeater Appearance: Compared to twisted sausages, the sausage filling and tying machine produces products with no extra casing lumps at both ends, making the appearance more attractive to shoppers and helping drive sales.;

7. Durable & Hygienic Build: Made with high-quality materials, the sausage binder machine and sausage threading machine in the line ensure durability and easy cleaning, complying with food safety standards and reducing the time and money spent on maintenance.

Parameter:

| Model | AK3200T+AKQ1200+AK800 |

| Total power | 10kw |

| Capacity | Max 800 knots/min |

| Sausage length | 20-250mm |

| Sausage diameter | ø9-40mm |

| High accuracy: | ±2mm/100mm error |

Our equipments can make all kinds of sausages:

Dried sausage/Fried sausage/Homemade sausage/French sausage/Flavor sausage/Salami/Ham/Hot dog/Liver Sausage/ Rice Sausage/Cuttlefish Sausage/Grilled sausage and so on.

Are you the manufacturer?

Yes, we are the only manufacturer of AOKAI brand.

What is the price term and payment method?

We can quote EXW, FOB, CIF and CNF price. And you can pay us by T/T, L/C or Western Union.

How can we see the working machines?

You are warmly welcome to visit our factory or we can have a video call to show you our factory and introduce the details of your interested machines on the spot.

Can you make customized designed products?

Yes, we have a professional technology team for new research and development.We can make the products according to customer's requirements, like the size,logo and details.

Warranty?

One year. We suggest you ask us about spare parts before you order.

How long is the delivery time?

About 2-4 weeks, depend on the products you order.