Bowl cutter is with a temperature detection device, it can measure the temperature change of raw materials during the chopping process; The bowl cutter adopts three cutters and cooperates with frequency conversion speed regulation to complete the chopping, emulsification and mixing at one time; The chopping time is short, the temperature of the product is small, and the taste and yield of the product are effectively improved;

EmailMore

The vacuum mixer can mix the product raw materials and auxiliary materials in a vacuum state, reduce the bubbles in the materials, increase the product flexibility, and extend the shelf life; The use of parallel double-shaft structure and inclined plate blades can make the materials make positive and negative circles at the same time during the turning process Movement, mix the material quickly and evenly; Vacuum blender machine adopts programmable controller and touch screen control, can store a variety of different mixing formulas, can set the vacuum degree, suitable for a variety of productprocess requirements.

EmailMore

The brine injection machine is the first piece of equipment for marinating meat, which can shorten the marinating time Brine injector is suitable for fresh meat or meat with bones at room temperature; Back-end commonly used tumbler.

EmailMore

Meat grinder take the lead in adopting the dragon-grinding technology to reduce the friction of the meat during the grinding process and maintain the taste of the meat; The unique design of the stainless steel minced meat part makes meat micer easy to feed the meat and increase the output; Motor overload automatic shutdown, automatic reset function;

EmailMore

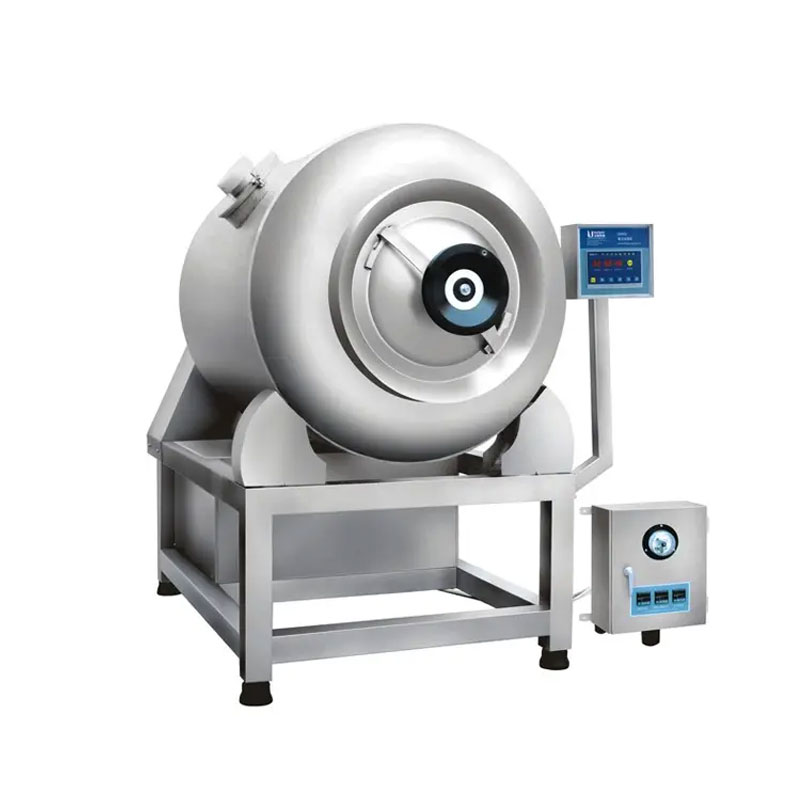

The vacuum tumbler is in a vacuum state, so that the meat is turned up and down on the drum bone, collided with each other, and beaten to achieve the effect of massaging and marinating; Vacuum meat massager improve the strength of the meat and the elasticity of the product, and increase the yield; The tumbling time, intermittent time and vacuum degree can be set according to different process requirements.

EmailMore

Frozen meat grinder is a common equipment for meat processing, which can directly mince unfrozen frozen meat; By changing the hole plate, various specifications of particles can be processed to meet different process requirements; Effectively reduce the production cost when used in conjunction with the frozen meat flaker; Made of high-quality stainless steel, with simple operation, stable performance, easy cleaning and high production efficiency.

EmailMore

Vacuum bowl chopper is with a temperature detection device, it can measure the temperature change of raw materials during the chopping process; The chopping and mixing machine adopts a combination of six cutters and cooperates with frequency conversion speed regulation to complete the chopping, emulsification and mixing at one time; The chopping and mixing time is short, the temperature of the product is small, and the taste and yield of the product are effectively improved; The pot speed, the gap between the chopping knife and the turning pot achieve a reasonable combination, so that the chopping product is more uniform.

EmailMore

The vacuum mixer can mix the product raw materials and auxiliary materials in a vacuum state, reduce the bubbles in the materials, increase the product flexibility, and extend the shelf life; The use of parallel double-shaft structure and inclined plate blades can make the materials make positive and negative circles at the same time during the turning process Movement, mix the material quickly and evenly; Vacuum blender machine adopts programmable controller and touch screen control, can store a variety of different mixing formulas, can set the vacuum degree, suitable for a variety of productprocess requirements;

EmailMore

Sausage smoking machine has steaming, drying, smoking function etc. Electric smoke oven is easy operation and cleaning, improve the taste of cooked meat/ dried tofu.

EmailMore

The meat slicer can control the advancing distance of the advancing device through the display screen to adjust the thickness of the cutting material. The design of the screw structure reduces the propulsion stagnation rate and improves the production efficiency and production quality. The meat material can be fed in steps, which can maximize the cutting accuracy during the cutting process. The meat slices are not sticking to the knife, and the thickness is even and neat.

EmailMore