INDUSTRIAL SOLUTIONS FOR SAUSAGE

Sausage

We provide high-performance systems for all sausage processing stages, from raw meat preparation to final casing and sealing.

Cutting System

A sequential processing chain ensures refined meat preparation through specialized separation, frozen meat conditioning, and adjustable thickness/dice customization.

Injecting System

Our precision-engineered injection systems utilize multi-zone needle arrays with adaptive pressure logic, ensuring uniform salt dispersion and microbial safety in sausage matrices.

Mincing System

Our industrial mincing systems feature multi-temperature grinders (frozen/fresh), single/dual-auger configurations, and automated density control, achieving repeatable texture uniformity for sausage formulations.

Mixing System

Our integrated mixing systems combine vacuum tumblers, emulsifiers, and multi-stage bowl cutters with precision temperature control, achieving homogenous protein bind and fat distribution in sausage matrices.

Filling System

Featuring adaptive pressure-flow systems with radial casing guidance, our solutions achieve homogeneous density distribution across natural and synthetic casings.

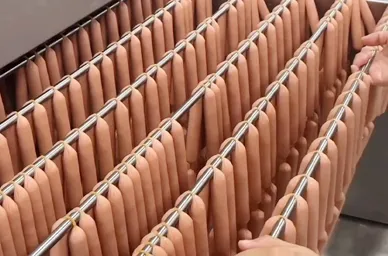

Forming System

Featuring synchronized motion control with multi-axis sealing systems, our solutions maintain dimensional accuracy across twisting, tying, and hermetic closure processes.

Smoking & Cooking System

Our precision-controlled curing systems combine dynamic heat distribution with balanced flavor infusion, ensuring uniform texture enhancement and aroma consistency.

Splitting System

Our tailored processing configurations employ guided surface refinement and sequential segmentation mechanisms to ensure residue-free interfaces and structural integrity.

Screening System

Advanced oscillating separation processes ensure thorough impurity isolation, including fragmented casings and production debris, through calibrated vibration phases.

Auto-Bagging System

Our continuous encapsulation systems synchronize product alignment, customized pouch formation, and vacuum-sealed barrier creation for shelf-stable packaging precision.

Auto-Boxing System

Synchronized container formation systems integrate carton erection, precision product loading, and pre-sealing activation in continuous workflows.

Auto-palletizing System

Our pallet stabilization systems synchronize baseplate positioning with robotic stacking mechanisms to ensure load optimization patterns.

Auxiliary Machines

Customizable add-ons such as sausage-loading aids, mobile trolleys, and tying stations improve workflow coordination without complex integrations.

WHAT MAKES US YOUR GO-TO CHOICE?

One stop whole line solution design

Including scheme consultation, whole plant planning, product research and development, production and sales, installation and commissioning

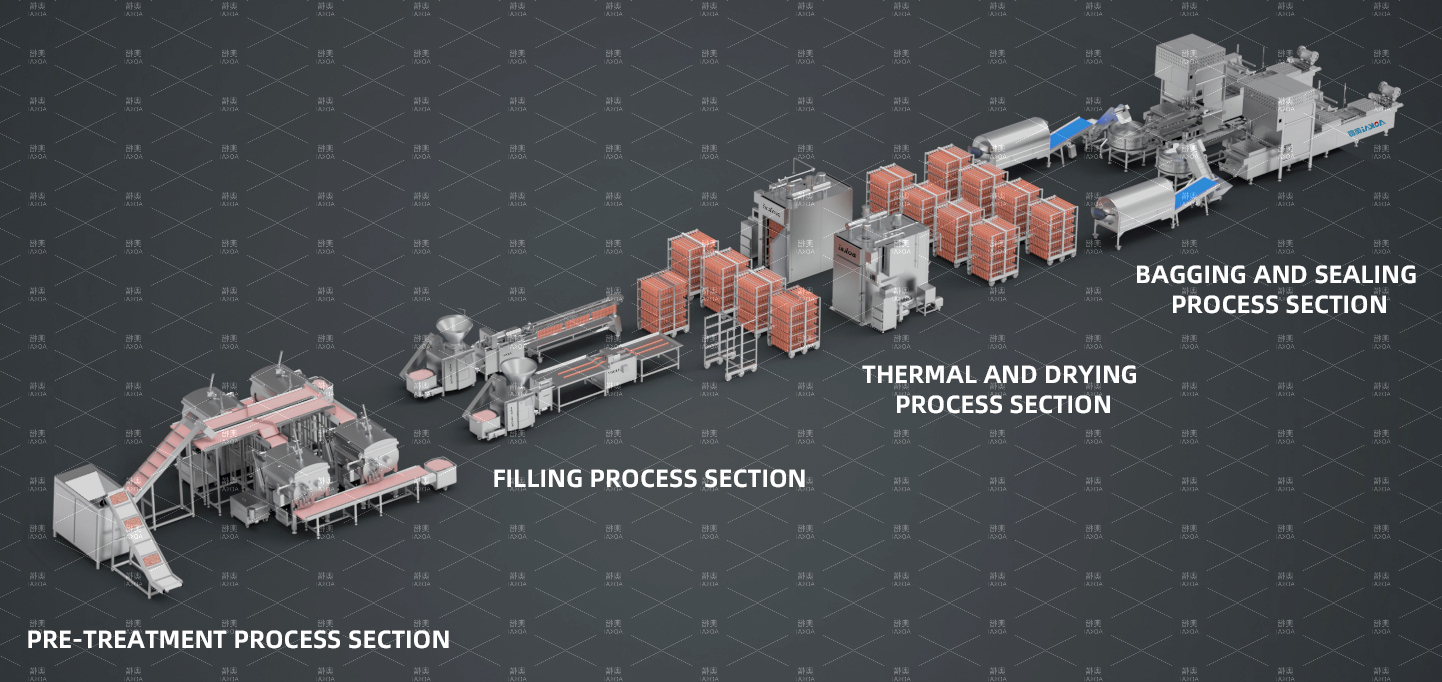

Modular processing full process

Including pre-treatment process section, filling process section, thermal and drying process section, bagging and sealing process section, packing and palletizing process section, etc.

Intelligent solution design

High degree of automation, saving labor, reducing costs and increasing efficiency.

24/7 online service

Provide free full line operation training and one-on-one after-sales service from the manufacturer.