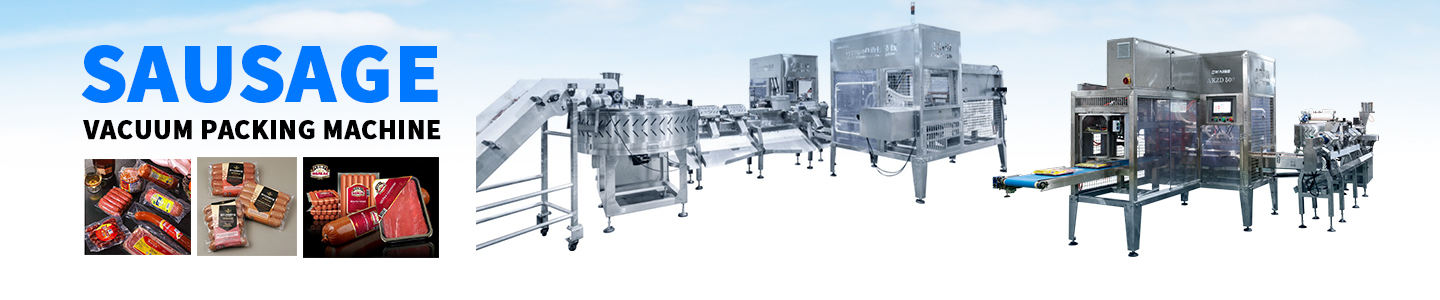

Food Vacuum Stretch Film Packing Machine

- Aokai / E-leading

- Foshan,Guangdong,China

- 30-35days

- 15 sets/month

Food Vacuum Stretch Film Packing Machine

Advantages

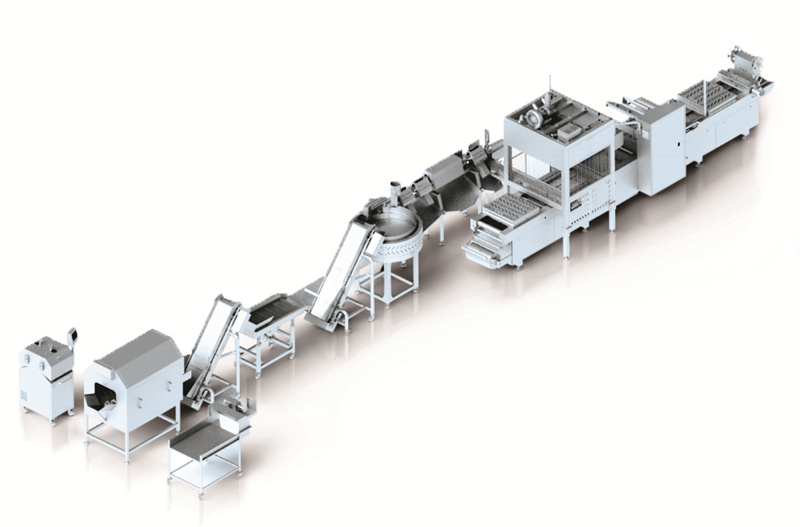

1. Vacuum thermoforming machine is high degree of automation, fast speed and strong compatibility.

2. The sealing is neat and matched with the code spraying machine module for customers to increase the code spraying machine.

3. Walk 5 steps a minute, walk smoothly, and roll back the cornea automatically.

4. Motor, reducer, vacuum pump and electrical components all adopt famous brand products at home and abroad with high stability;

5. The whole machine is made of SUS304 stainless steel and aluminum alloy;

6. Models and molds can be customized according to customers' products;

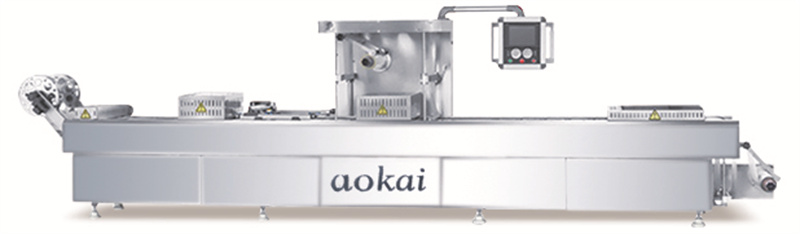

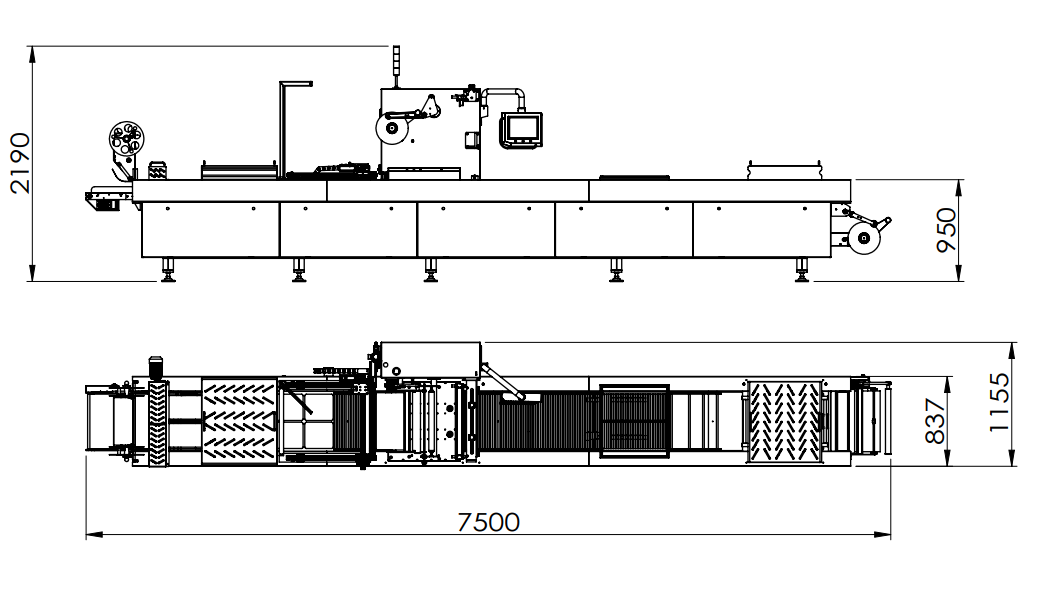

Model | Power (KW) | Dimension (mm) | Weight (kg) | Air pressure (Mpa) | Vacuum (Mpa) | Speed (times/min) |

AKLS640 | 15 | 8500*1255*2290 | 2800 | 0.6~0.8 | -0.1 | 5~7 |

AKLS580 | 12 | 7500*1155*2190 | 2500 | 0.6~0.8 | -0.1 | 5~7 |

AKLS520 | 10 | 7200*940*1850 | 2060 | 0.6~0.8 | -0.1 | 5~7 |

AKLS420 | 8 | 5400*840*1850 | 1650 | 0.6~0.8 | -0.1 | 5~7 |

Features:

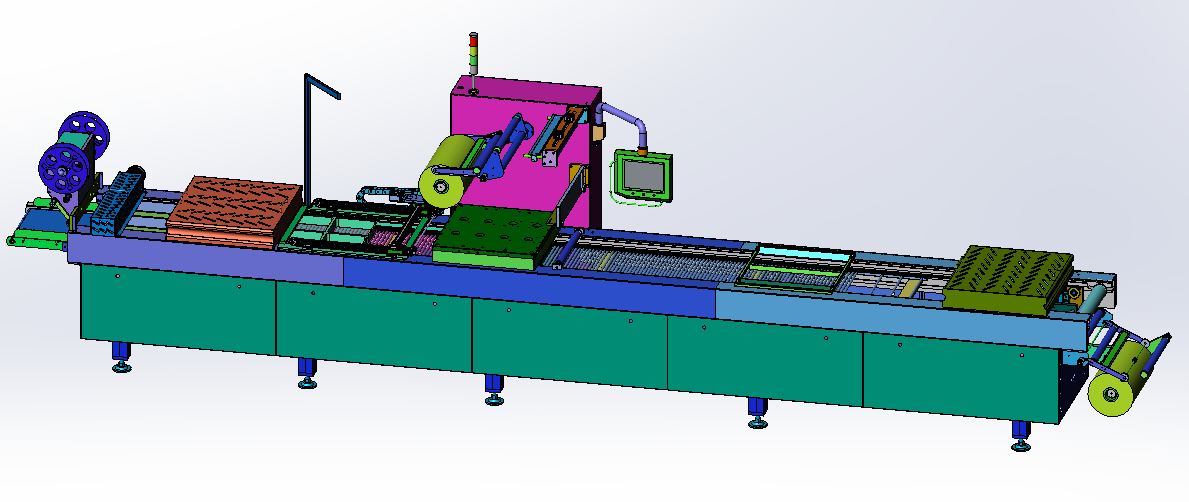

Adopt German Siemens PLC computer control.

According to the needs of different customer product packaging, we can customize the production of special molds, and at the same time, one machine can produce a variety of products.

The packaging equipment is equipped with a safety automatic protection system to prevent safety hazards ,which caused by operator misoperation or illegal operation.

The key parts adopt the maintenance-free system and the imported oil-free lubrication transmission, so that the equipment does not need to be refueled during the normal production process, ensuring that the packaged products are free of pollution.

The lifting mechanism introduces German technology, the lifting speed is uniform, stable, balanced, the failure rate is extremely low, and the quality stability of the equipment itself is improved.

For the slitting knife system, the overall cutting knife has been customized according to the user's product. When making different products, it is easy to replace and has no potential safety hazards. It only takes 30 seconds.

Cross-cutting knife system, all using hidden cutters to ensure the safety of the equipment during the working process

Quality Requirement:

1. The probability of More or Less is 3‰ after successful commissioning of the equipment.

2. Sausages shall not be damaged or broken during bagging. If the upstream products are damaged or broken, that the above requirement is not applicable.

3. Error probability of bagging is less than 5 ‰.

Are you the manufacturer?

Yes, we are the only manufacturer of AOKAI brand.

What is the price term and payment method?

We can quote EXW, FOB, CIF and CNF price. And you can pay us by T/T, L/C or Western Union.

How can we see the working machines?

You are warmly welcome to visit our factory or we can have a video call to show you our factory and introduce the details of your interested machines on the spot.

Can you make customized designed products?

Yes, we have a professional technology team for new research and development.We can make the products according to customer's requirements, like the size,logo and details.

Warranty?

One year. We suggest you ask us about spare parts before you order.

How long is the delivery time?

About 2-4 weeks, depend on the products you order.