Streamlined Processes

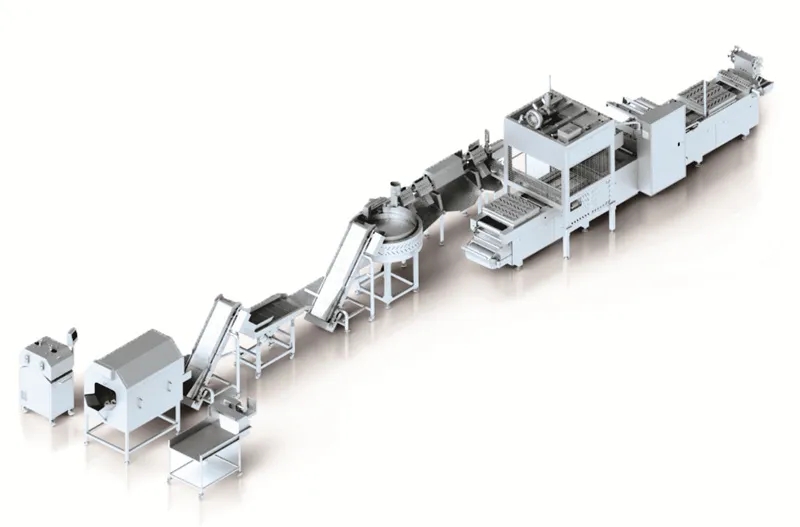

Automated sausage packaging lines integrate multiple functions, allowing for seamless transitions between stages of production. Machines like the sausage loader, food vacuum packaging machine, and cling film packaging machine work in harmony to minimize downtime and speed up the overall packaging process.

Increased Production Speed

Automation enables higher throughput rates compared to manual packaging. Automated systems can operate continuously, significantly increasing the number of sausages packaged per hour. This efficiency is crucial for meeting consumer demand, especially in high-volume production settings.

Consistency and Quality Control

Automated sausage packaging machines ensure uniformity in packaging, which is vital for maintaining product quality. Precise control over packaging parameters reduces variability, leading to better sealing, less spoilage, and improved presentation. This consistency helps build consumer trust in the brand.

Reduced Labor Costs

By minimizing the need for manual labor, automation reduces labor costs associated with packaging. Automated systems require fewer personnel to operate, allowing companies to allocate resources more effectively. This shift not only cuts costs but also reduces the risk of human error in the packaging process.

Enhanced Safety

Automation decreases the risk of contamination by reducing human contact with the product. Machines like the food vacuum packaging machine are designed to operate with minimal intervention, ensuring that hygiene standards are maintained throughout the packaging process. This is particularly important in the food industry, where safety is paramount.

Real-Time Monitoring and Data Collection

Automated packaging lines often include monitoring systems that collect data in real time. This data can be analyzed to identify inefficiencies and optimize processes. For instance, insights into packaging times and materials used can help streamline operations and reduce waste.

Flexibility and Customization

Modern automated sausage packaging machines can be easily adjusted to accommodate different product sizes and packaging types. This flexibility allows manufacturers to quickly switch between products without significant downtime, making it easier to adapt to changing market demands.

Conclusion

The integration of automation in sausage packaging lines significantly enhances efficiency, from streamlining processes to improving quality control. By utilizing advanced sausage packaging machines, food vacuum packaging machines, and cling film packaging machines, companies can achieve higher production speeds while maintaining safety and consistency.

For businesses looking to optimize their packaging operations, Foshan Aokai Machinery Technology Co., Ltd. offers state-of-the-art automated solutions designed to improve efficiency and meet the evolving demands of the sausage packaging industry.