In the fast-evolving food industry, efficient and quality packaging is paramount, especially for perishable items like sausages. One technology that stands out in this domain is the thermoformer machine. This article delves into how thermoformers enhance sausage packaging, focusing on their benefits and applications.

Introduction to Thermoformers

Thermoformer machines are specialized equipment that shape plastic into custom packages by heating and molding. They create vacuum-sealed or modified atmosphere packaging (MAP) that effectively preserves the freshness of sausages. This innovative approach ensures that sausages remain safely packaged, minimizing exposure to contaminants and extending their shelf life.

Extended Shelf Life

One of the standout features of thermoformers is their ability to significantly extend the shelf life of sausages. By employing vacuum sealing or MAP, these machines reduce oxygen levels within the packaging, which slows down the spoilage process. This is crucial in the sausage industry, where maintaining freshness is essential for flavor and safety. The use of Food Vacuum Stretch Film Packing Machines can complement this process by further enhancing the sealing capabilities and ensuring optimal freshness.

Product Protection

Thermoformed packaging provides a robust barrier against external factors such as moisture, contamination, and physical damage. Sausages can be delicate, and effective packaging is vital for protecting them during transport and storage. The durability of thermoformed packages ensures that products reach consumers in perfect condition, enhancing overall customer satisfaction.

Material Efficiency

Another significant advantage of thermoformers is their material efficiency. These machines create packages tailored to the exact dimensions of the sausages, which reduces excess plastic waste. This not only aligns with sustainability goals but also results in cost savings for manufacturers. Utilizing Swing Vacuum Packaging Machines can further optimize this process by allowing for quick and efficient packaging of different sausage varieties.

Versatile Applications

Thermoformers are versatile tools capable of producing various packaging forms. Whether it’s vacuum-sealed packages, custom-fit solutions, or portion-controlled packs, these machines can cater to different types of sausages. The adaptability of Dual Channel Sausage Feeding Machines can enhance this versatility, allowing for efficient packing of diverse sausage shapes and sizes.

Improved Packaging Efficiency

With automation at the forefront, thermoformer machines streamline the packaging process significantly. They reduce the need for manual labor, speed up production, and minimize human error. By integrating Automatic Sausage Loader and Packaging Machines, manufacturers can achieve a seamless packaging workflow, enhancing overall efficiency and productivity.

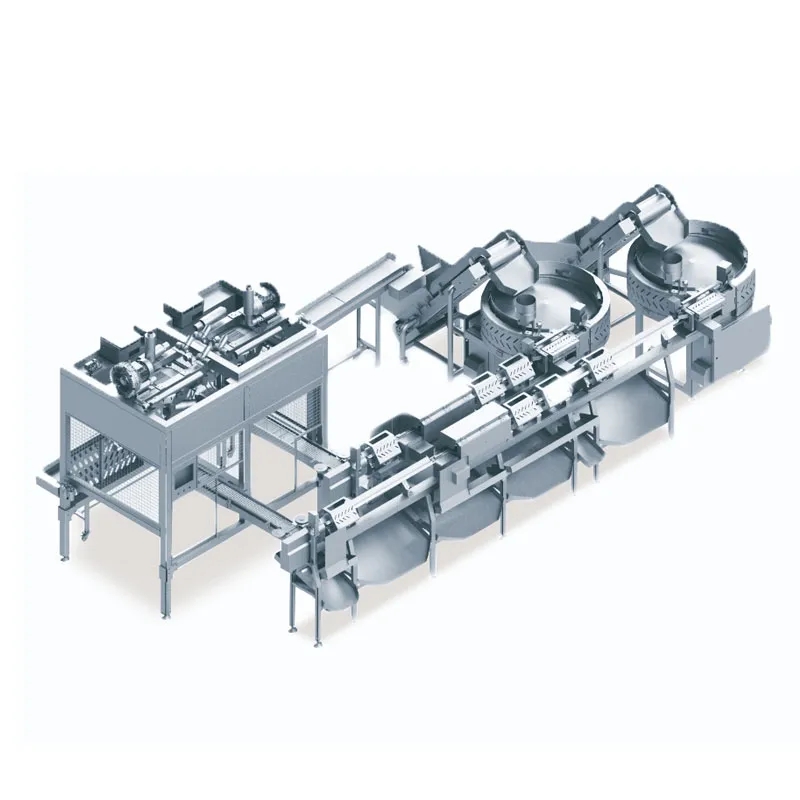

Integration with Other Equipment

Thermoformers can be seamlessly integrated into larger automated packaging lines, further improving operational efficiency. This integration allows for synchronized operations with loaders, conveyors, and other equipment, resulting in reduced downtime and increased output. Such comprehensive systems are essential for modern sausage production, where efficiency is critical.

In conclusion, thermoformer machines are transforming sausage packaging by enhancing efficiency, extending shelf life, and improving product protection. Their versatility and automation capabilities make them invaluable in the food packaging industry.

For businesses looking to elevate their packaging processes, exploring advanced machinery options can yield significant benefits. Foshan Aokai Machinery Technology Co., Ltd. specializes in providing state-of-the-art packaging solutions that can help optimize your sausage production line.