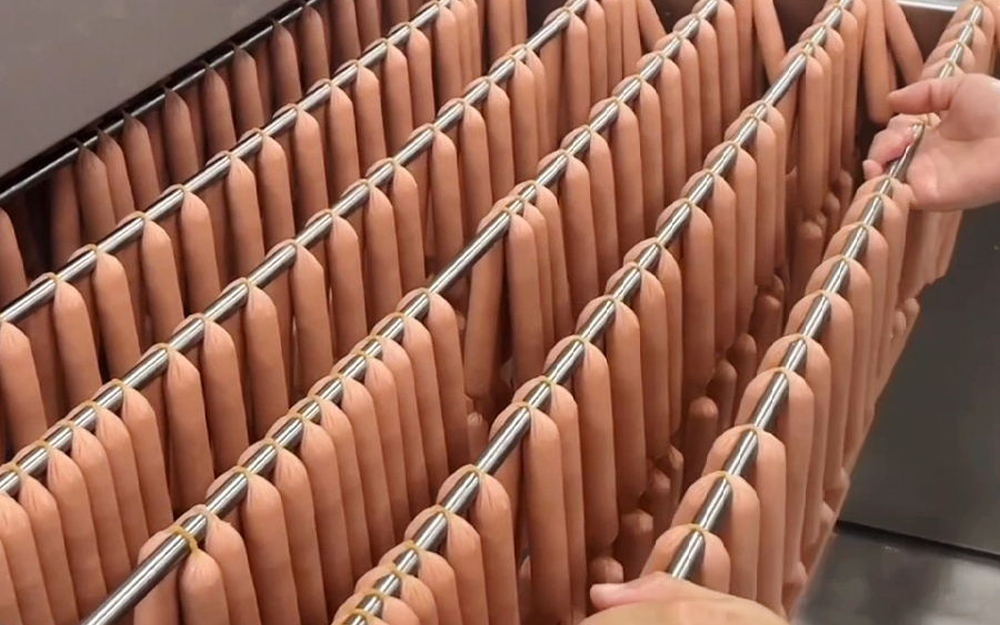

Commercial Sausage Filling Machine

AK6200

Achieves precise filling, portioning, and shaping via vacuum-sealed inner cam vane pump. Prevents oxidation and heat damage, ensuring air-free, high-density texture with optimal taste.

Achieves precise filling, portioning, and shaping via vacuum-sealed inner cam vane pump. Prevents oxidation and heat damage, ensuring air-free, high-density texture with optimal taste.

Utilizes vacuum-controlled filling for air-free consistency (±1.5g/100g) across 5g-10kg ranges. Compatible with natural/collagen/plastic casings and integrates seamlessly with twisting/clipping systems. SUS304 alloy ensures durability, hygiene, and stable high-speed production.

PRODUCT PARAMETERS

Vacuum Filling Machine AK6200

| PARAMETER TYPES | PARAMETER VALUES |

|---|---|

| Total power and power supply | 9kW / 380V+N+PE |

| Filling machine's direct filling capacity | 4000kg/h (Depending on the product being produced) |

| Improve raw material functionality | Increase volume: 250 ~ 300L(rise) |

| Filling machine vacuum pressure | 0 ~ -0.1mpa |

| Maximum lifting weight | 250kg |

| Hopper capacity | 250L |

| Quantitative accuracy | ±1g/100g(minced meat); ±2g/100g(meat cubes) |

| Speed | Stepless speed regulation 1 - 100% |

| Overall weight | 1350kg |

| External Dimension (mm) | 2460x1360x2255(LxWxH) |

PRODUCT HIGHLIGHTS

Vacuum Filling Machine AK6200

High-efficiency Filling Capacity

AK6200 uses vacuum feeding, handling 3000-4000kg/h meat filling – 30% more productive than traditional models, ideal for large-scale production.

With Precise Dosing Function

Dosing range 5g~10000g, with excellent accuracy – ±1.5g/100g for minced products and ±2g/100g for block products.

All Stainless Steel Body

The food-contacting parts are made of 304 stainless steel, and the whole machine meets food-grade hygiene standards. It is corrosion-resistant and easy to clean, effectively preventing bacterial growth and ensuring product safety.

Yes, we are the only manufacturer of AOKAI brand.

We can quote EXW, FOB, CIF and CNF price. And you can pay us by T/T, L/C or Western Union.

You are warmly welcome to visit our factory or we can have a video call to show you our factory and introduce the details of your interested machines on the spot.

Yes, we have a professional technology team for new research and development.We can make the products according to customer's requirements, like the size,logo and details.

One year. We suggest you ask us about spare parts before you order.

About 2-4 weeks, depend on the products you order.