As global meat processors face rising labor costs, tighter margins, and increasing pressure to stabilize product quality, the question is no longer whether to automate—but how to do it efficiently. In this context, the one-stop meat processing solution is emerging as a practical answer for manufacturers seeking measurable yield gains and long-term operational resilience.

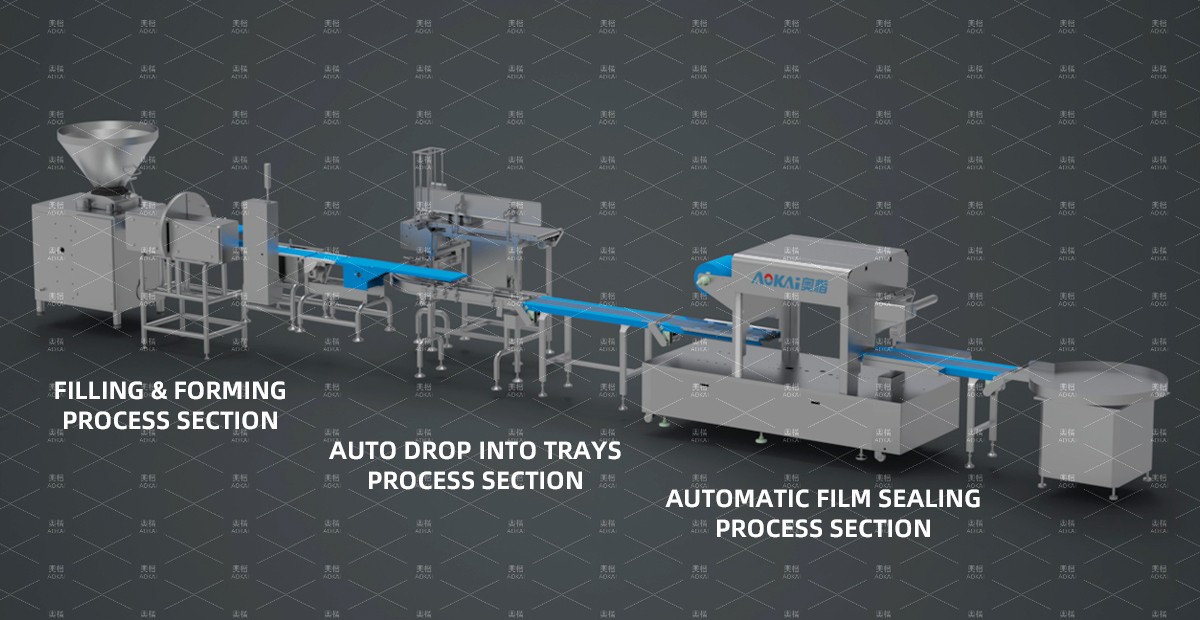

Rather than assembling fragmented equipment from multiple suppliers, leading processors are shifting toward integrated systems that align grinding, forming, filling, cooking, and packaging under one coordinated production logic. This structural shift is redefining how factories approach efficiency, cost control, and scalability.

Industry Reality: Yield Loss and Labor Dependency Are Still the Hidden Costs

In traditional meat plants, yield loss often occurs invisibly—through inconsistent portioning, over-trimming, drip loss during filling, or unstable temperature control. At the same time, labor-intensive steps such as manual stuffing, shaping, and sorting remain vulnerable to workforce shortages and training variability.

According to industry benchmarks, processors without integrated automation typically lose 3–10% of raw material value across a full production cycle. This is why meat production yield improvement has become a strategic KPI, not merely a quality metric.

A modern one-stop meat processing solution addresses this challenge at the system level, ensuring that yield optimization is engineered into every stage rather than corrected after losses occur.

From Fragmentation to Integration: The One-Stop Approach Explained

Aokai, founded in 2008 and based in Foshan, China, has spent over 17 years refining this integrated philosophy. Instead of offering isolated machines, Aokai designs scalable processing lines that combine standard equipment with customized modifications—allowing manufacturers to match output volume, product type, and plant layout precisely.

This model supports diverse production needs, from sausages and bacon to advanced formats like the Meat Baton Line and Patty Processing Line, while maintaining centralized control and consistent throughput.

By deploying a one-stop meat processing solution, manufacturers can synchronize mechanical performance, digital monitoring, and hygienic design across the entire workflow.

How Automation Directly Improves Yield and Cuts Labor

1. Precision Portioning and Intelligent Control

Advanced portioning systems ensure gram-level accuracy during forming and filling. This alone can deliver a 5–8% meat production yield improvement by eliminating overfill and rework.

2. Labor Substitution Without Quality Trade-Offs

Modern labor-saving meat equipment replaces manual sorting, filling, and shaping with automated modules. On a single integrated line, labor requirements can drop by 40% or more, while output consistency improves.

3. Process-Specific Engineering

Different meat products demand different process logic. For example:

Jerky lines require stable airflow and intelligent temperature zoning

Bacon lines depend on uniform thickness control

The Meat Baton Line emphasizes shape integrity and weight consistency

The Patty Processing Line prioritizes forming speed without fiber damage

A unified system allows these parameters to be optimized without disrupting upstream or downstream processes.

Key Performance Comparison: Traditional vs Integrated Lines

| Parameter | Traditional Setup | One-Stop Integrated Line |

| Raw material utilization rate | 90–93% | 95–98% |

| Average labor per production line | 12–15 workers | 6–8 workers |

| Portioning deviation | ±3–5% | ±0.5–1% |

| Daily output stability | Medium | High |

| Changeover efficiency | Low | Modular & fast |

| Compliance consistency | Operator-dependent | System-controlled |

This table illustrates why labor-saving meat equipment is no longer a luxury, but a baseline requirement in competitive markets.

Experience-Driven Optimization Across Product Categories

Aokai’s engineering teams apply accumulated field data from installations in the US, Mexico, and Southeast Asia to fine-tune each line. In jerky production, intelligent temperature control ensures even texture and color. In sausage filling, anti-drip nozzle design significantly improves acceptance rates and hygiene outcomes.

Such refinements directly contribute to meat production yield improvement, while also lowering downtime and maintenance frequency—two factors often overlooked in ROI calculations.

Why One Supplier Matters More Than Ever

Managing multiple equipment vendors often results in mismatched interfaces, fragmented after-sales support, and delayed troubleshooting. A single one-stop meat processing solution eliminates these gaps by centralizing responsibility.

With an experienced after-sales team and full-cycle manufacturing under international standards, Aokai ensures stable long-term operation—not just successful installation.

Frequently Asked Questions (FAQ)

Q1: Is a one-stop system only suitable for large factories?

No. Modular design allows small and mid-sized processors to adopt a one-stop meat processing solution incrementally while planning future expansion.

Q2: How fast can labor savings be realized?

Most customers see measurable labor reductions within the first three months of commissioning labor-saving meat equipment.

Q3: Can existing lines be upgraded instead of replaced?

Yes. Aokai specializes in integrating new modules—such as portioning or forming units—into existing Patty Processing Line or sausage lines.

Q4: Does automation affect product authenticity?

On the contrary, controlled processing improves consistency while preserving texture, especially in the Meat Baton Line.

Q5: What markets are currently adopting integrated solutions fastest?

North America and Southeast Asia lead adoption, driven by labor shortages and demand for consistent quality.

A Strategic Move Toward Sustainable Profitability

The future of meat processing lies in systems that do more with less—less waste, less labor dependency, and less operational uncertainty. Integrated automation is no longer a trend; it is a structural upgrade.

For manufacturers seeking scalable growth, predictable costs, and reliable meat production yield improvement, investing in a one-stop meat processing solution supported by proven engineering and global service capability is a decisive step forward.

Call to Action

If your factory is evaluating upgrades for a Meat Baton Line, Patty Processing Line, or full plant automation, now is the time to rethink fragmentation. Partnering with a supplier that delivers complete, customized, and labor-saving meat equipment can redefine both productivity and profitability.