On September 17, 2025, the 23rd China International Meat Industry Exhibition (CIMIE 2025) concluded successfully in Xiamen. As a UFI-certified, Asia-leading, and highest-standard professional event in the meat industry, this edition not only set a record with a historic exhibition area of nearly 110,000 square meters but also gathered over 2,000 enterprises and more than 100,000 professional visitors from over 40 countries and regions worldwide. Covering the entire meat industry chain, it became a core platform for understanding industry trends, connecting global resources, and showcasing cutting-edge technologies.

Since its inception in 2003, CIMIE has been deeply rooted in the industry for 23 years, attracting over 520,000 buyers, distributors, and experts. It consistently drives technological innovation and trade cooperation in the meat industry. This edition of the exhibition, themed "Full Chain Synergy, Intelligent Innovation for the Future," comprehensively covers terminal products such as fresh meat, processed meat products, and deep-processed meat products, as well as all segments of the industrial chain, including slaughter equipment, processing machinery, packaging equipment and materials, food ingredients, cold chain logistics, and environmental protection equipment, creating a panoramic showcase of the meat industry ecosystem. Concurrently held are over 200 industry forums, product launch events, and industry summits, focusing on hot topics such as meat processing automation, food safety control, and low-carbon production, serving as a bridge for in-depth exchanges and collaborative development among industry professionals.

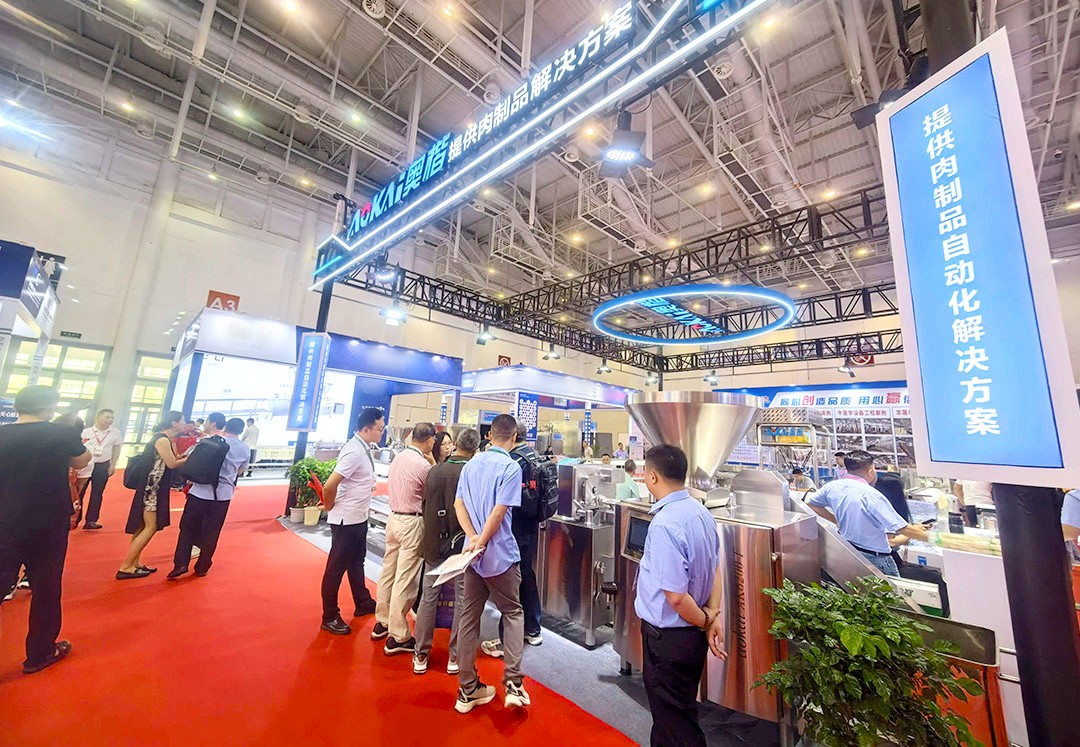

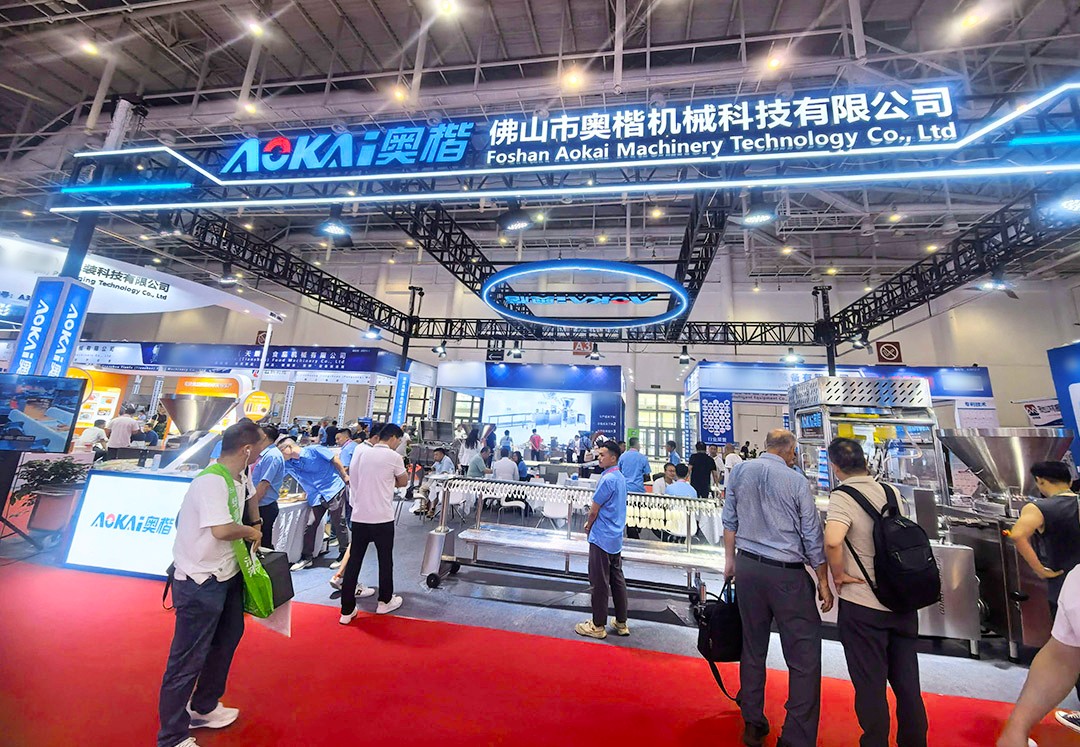

As a provider of complete automation solutions for the meat product industry, Aokai Machinery (established in 2008, a modern meat product machinery manufacturer integrating research and development, production, and sales) was invited to participate in the exhibition. With years of deep industry experience, comprehensive solutions, and multiple innovative new products, it became the focus of the exhibition and attracted a large number of meat processing enterprises, distributors, and industry experts to stop and negotiate. During the exhibition, the technical team of Aokai Machinery was present throughout the entire process, engaging in multidimensional and in-depth exchanges with customers from all over the country and overseas on pain points, production capacity upgrade needs, and technological innovation directions in the meat processing industry. They accurately explored cooperation potential, listened to customers' customized needs, and accumulated valuable experience for subsequent product optimization and solution upgrades.

At this exhibition, Aokai Machinery showcased a variety of automated new products that are suitable for sausage processing and general meat product processing, accurately fitting the current development trend of "high efficiency, precision, intelligence, and energy conservation" in the meat processing industry, helping enterprises break through production capacity bottlenecks and improve product consistency:

1. Sausage quantitative filling and tying production line: Adopting a precise measurement control system, it can achieve quantitative filling of different specifications of sausages with small filling errors. Combined with automated tying functions, it greatly reduces manual intervention, improves production efficiency, and ensures that each sausage has uniform weight and regular appearance. It is suitable for various categories such as pork sausage, beef sausage, chicken sausage, etc. and is widely used in medium and large sausage processing enterprises.

2. Sausage filling and knotting production line: Integrated filling and knotting functions, easy to operate, flexible adjustment of knotting spacing and sausage length, suitable for various materials such as collagen casing and natural casing, solving problems such as low efficiency and uneven force caused by manual knotting, cash damage, and product failure, while balancing production speed and product quality.

3. Wire tying and hanging machine: Automatically completes the hanging process of sausage wire tying, connects with the filling and tying production line, realizes a closed-loop process, reduces manual handling and hanging errors, lowers labor costs, and avoids damage to sausages during transportation, adapting to the needs of large-scale continuous production.

4. Single channel feeder (sausage automatic bagging machine): Using intelligent conveying and arranging technology, sausages can be automatically sorted, orderly arranged, and bagged, avoiding the problem of manual disorderly arrangement, improving packaging efficiency, adapting to different packaging requirements, and helping enterprises achieve automation upgrades in the packaging process.

5. Vacuum mixer: Adopting a vacuum sealed design, air is avoided from mixing during the mixing process to prevent oxidation and discoloration of meat products. At the same time, it ensures uniform mixing of meat, auxiliary materials, and spices, improves product taste and cohesion, reduces raw material waste, and is suitable for processing various meat products such as sausages, minced meat, and meat patties, balancing practicality and energy efficiency.

Based on the quality concept of "creating products with character and creating exquisite products", Aokai Machinery's products are made of food grade 304 stainless steel material, which meets global food safety standards such as FDA and EU, and has modular design characteristics. They can be flexibly combined according to the production scale and site size of the enterprise, adapting to diverse needs from small and medium-sized processing plants to large listed companies. Over the years, Aokai Machinery has established long-term cooperation with numerous large food enterprises, and has a good reputation and high market share in the industry.

At present, the meat processing industry is accelerating its transformation towards automation and intelligence. Issues such as labor shortage, low production efficiency, and poor product consistency have become key constraints on the development of enterprises, and professional automated processing equipment has become the core support for enterprises to break through. Especially in the context of the global meat production entering the 4.0 era, intelligent technology and human-machine interaction optimization have become innovative directions in the industry. Aokai Machinery accurately grasps this trend, continues to deepen its cultivation in the field of meat processing automation, focuses on cutting-edge technology research and development, and provides customers with one-stop full process services from solution consulting, whole plant planning, to product research and development, installation and commissioning, and after-sales service.

This appearance at CIMIE 2025 is not only an important opportunity for Aokai Machinery to showcase its technological strength and product advantages, but also an important measure to explore development opportunities with industry colleagues and promote the upgrading of meat processing equipment. In the future, Aokai Machinery will continue to uphold the core values of "going all out, creating value, altruism and gratitude, and integrating knowledge and action". With a sound R&D system and production capacity, we will continuously introduce automation solutions that better meet industry needs, help global meat processing enterprises reduce costs and increase efficiency, enhance core competitiveness, and work together to build an efficient, safe, and sustainable meat industry ecosystem.

If you are looking for automation solutions for sausage processing and meat product assembly lines, or would like to know the detailed parameters of Aokai Machinery's new products at the exhibition, you can contact us through official channels such as the official website and email to obtain customized solutions and product quotations.