How is Harbin Red Sausage made?

2023-09-21 17:31How is Harbin Red Sausage made?

Harbin Red Sausage has been manufactured in Harbin, the capital of Heilongjiang province in the northeastern area of China. The province shares the border with Russia and in 1900’s many Russians, Poles and Lithuanians escaped horrors of war in their countries and settled in Harbin. They brought their own cuisine and sausage making skills and Harbin is renowned for its culinary dishes. In March 1909, a Russian immigrant, Ivan Yakovlevich Churin established “Churin’s Sausage Factory and started production of northeastern style sausages employing Lithuanian staff. Harbin Red sausage is a typical cured and smoked pork sausage as they were made in Poland or Lithuania. The sausage was commonly called “Li Dao Si” sausage, some called it “Kazakh red sausage”, and became enormously popular with locals. In time, the sausage became popular all over China and in other southeastern Asia countries.

Here are the raw materials and equipment suggested: pork, casings, starch, soy protein isolate, salt, nitrate, pepper, MSG, garlic, casings, cooking pot, meat grinder, mixer, sausage machine, smoke furnace Process flow: Ingredients One thawing (acid discharge) one bone (fat cut) one dividing one salting one ground meat one filling one roasting one steaming one smoking one finished product one low temperature storage formula: pig lean 38kg, pig fat 12kg, starch 3.0kg, MSG 0.045kg, pepper 0.045kg, garlic 0.15kg, Sodium nitrate 0.0025kg, refined salt 1.75~2kg.

Production steps:

Step 1. Unfreezing

If frozen meat is selected, it should be thawed and acid removed during processing. The temperature of acid discharge is 0-5°C, and the relative humidity is about 85% for 15~24h. Frozen meat raw materials need to be thawed, can be thawed with tap water spray or spray. The thawing temperature should be controlled at about 12°C.

Step 2.Trim

The raw meat for the production of enema should choose fresh pork or beef with low fat content and good knot strength, or frozen fresh pork or beef, requiring the removal of small bones, the skin of the meat, and the repair of fat, tendon, blood clots, lymph nodes, etc. Finally cut into fist-sized pieces, remove the soft fat from the pork fat and cut into squares. 3

Add 3~5kg of refined salt for every 100kg of raw meat. Spring and summer 4kg, autumn and winter 3kg, nitrate 0.05kg, when the muscle block is pickled with marinade, do stir evenly, and then sent to the curing room in a container that is not easy to oxidizing and rusting, press tightly, fat curing without nitrates, add 3.5-4kg salt every 100kg. The curing method is the same as muscle curing. The curing temperature should be controlled between 8 and 13C, the relative temperature is controlled at about 90%, the curing time is 72h for muscle and 24 to 48h for fat.

Step 3: Marinate

Signs of maturity:

The fat has no oxidation odor, odor, and the color of the meat is consistent, the hand is tightly pressed without soft feeling, the color of pork and beef is bright rose red, all become red or more than 80% become red, the smell is normal, there is no ammonia odor and hydrogen sulfide odor, the adhesion is sufficient, and the elasticity is full.

Step 4. Cut fat into pieces

Choose cured stearin as the best raw material, block shape to be consistent, each 10mm.

Step 5. Make the filling

First check whether the muscle is 80% or all red, otherwise it should not be used, and then use 3mm leaky eye meat grinder to ground the muscle, mixing should be mixed first with the muscle fiber thicker beef, and then add the muscle fiber finer pork seasoning mix evenly, rich adhesion and elasticity is good. In order to prevent the phenomenon of fat immersion, the temperature of the filling should be controlled at about 16C. Therefore, when adding water, partial ice chips can be used instead.

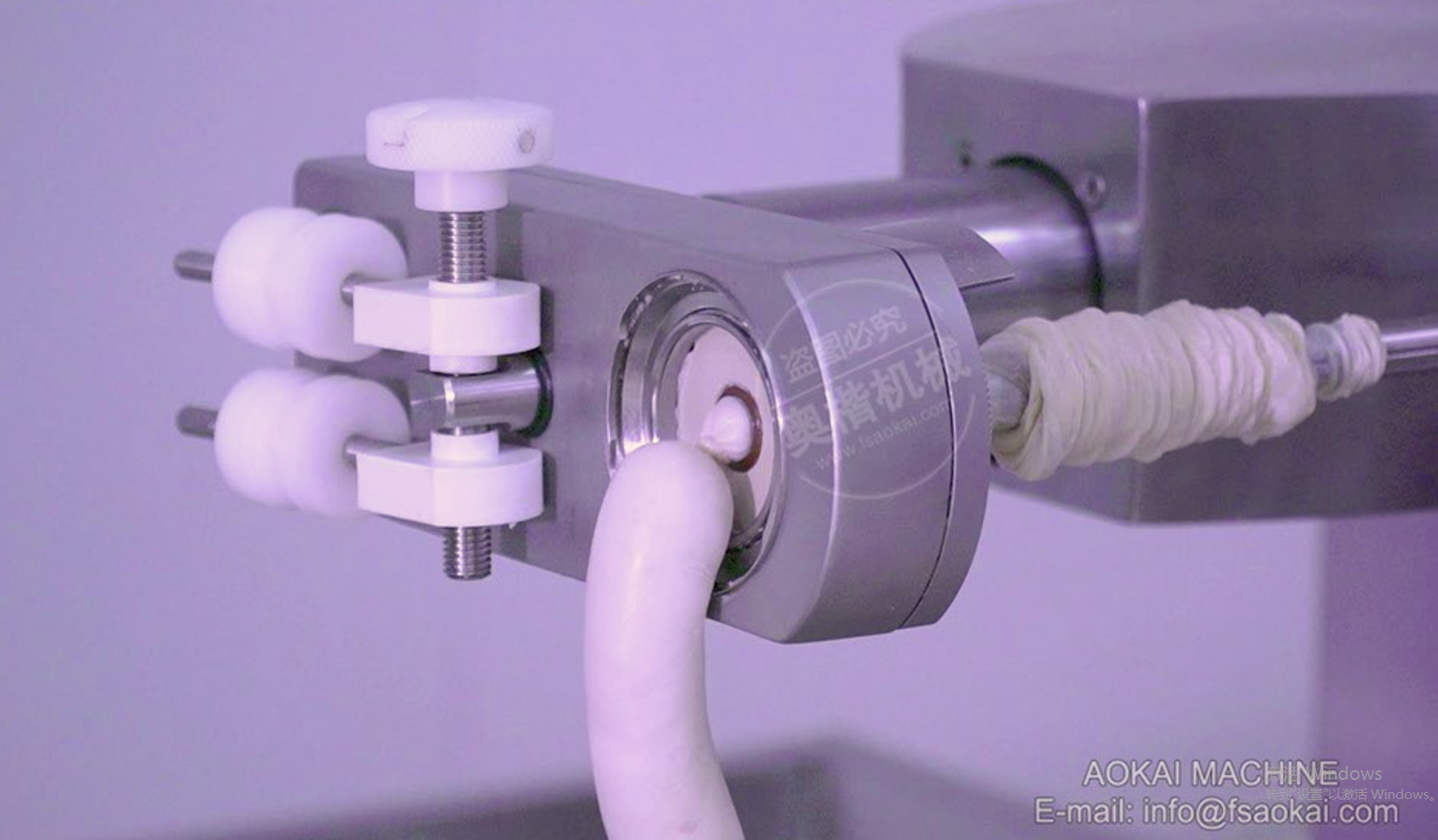

Step 6. Irrigation

The casing should be properly washed from pig intestine or cow intestine.

Before the irrigation, the salted casings should be soaked in water for 1.5~2h, the tightness should be moderate during the irrigation, and then knotted (18~22cm per section) and pierced, but there should be no extrusion between intestinal nodes.

Step 7 Bake

Generally, dry broad-leaved trees or anthracite are used as fuel, the furnace temperature is 90C, the time depends on the thickness of the intestine, generally between 20 and 30min, the surface of the baked intestine is dry, the casing is transparent, and some or all of the color of the meat filling is subject to.

Step 8. Cook over heat

Two methods, one is direct steam cooking after the barbecue, the other is boiled, the initial temperature of the pot is generally maintained at 90-92°C, the temperature is 84°C after the pot, and the time is 25 to 30min (depending on the thickness of the intestine). The temperature during cooking must be stable and consistent, to prevent sudden high and low, at the same time, the time must be accurate, and when the central temperature of the intestinal body reaches 74°C, the pot can be cooked.

Step 9. Smoking

Indoor meat products should be evenly hung to avoid sticking to each other. The fuel should be dry broad-leaved wood rods and wood chips, the smoking room is placed in a pile, quantitative wood rods, and then the wood chips are covered on the wood rods, pressed and lit, the smoking time is about 8h, the temperature is 35-55-75℃.

Step 10. Cool finished product out of oven